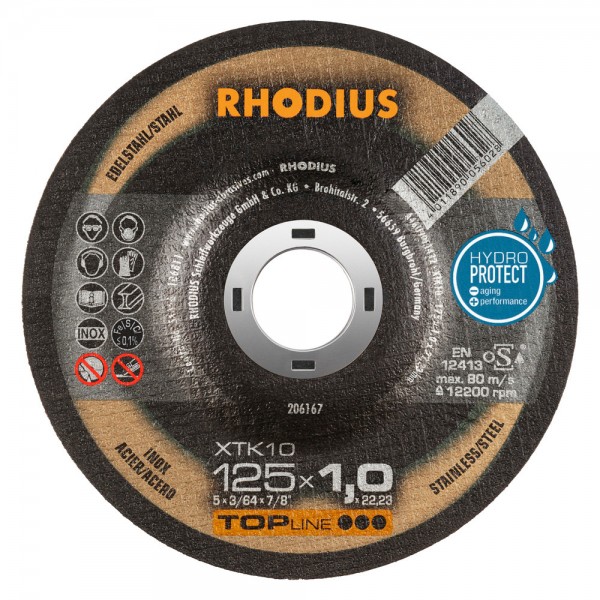

XTK10

XTK10

Content: 25 Unit

Prices incl. VAT plus shipping costs

- Order number: 206166

- Please select your desired product variant here:

Ultra high-performance thin cutting disc for demanding user requirements.

Machine suitability:

The XTK10 cutting disc is suitable for freehand use on angle grinders.

Material suitability:

The XTK10 has been designed especially for use on stainless steel (SST, Inox), e.g. 1.4031 (X5CrNi18-10 or 304), steel (carbon steel – also termed structural steel, St37, S235JR and 1.0037) and cast steels.

Structure and production:

The cutting disc contains high-quality corundum (aluminium oxide) and 2 full-coverage glass cloth layers. The minimum side load for the cutting disc as defined by EN 12413 and oSa is 40 N (50 N from a diameter of 150 mm). The expiry date (three years) is embossed in the disc hole ring. Consistently high quality is ensured by sophisticated in-process controls applied during manufacturing. To ensure a maximum level of safety, every thousandth disc is tested destructively. This disc features a straight shape (shape 42). The cutting disc is especially stable during cutting.

Quality:

With the XTK10, users get the best RHODIUS tool in its category. RHODIUS TOPline products represent a maximum level of performance and quality.

Applications:

The XTK10 offers an impressively long lifetime (tool life) during use, even in solid material, combined with a very aggressive, light and fast cut. Precise work when processing thin-walled material is also easy to achieve. The disc features minimal sparking, low dust generation and exceptional, vibration-free operation. All of which makes work easier and is especially cost-effective. The disc achieves low angular deviation thanks to its depressed shape. This quality RHODIUS tool is an especially good choice for cutting structural steel, tool steel, spring steels, thin-walled metal sheets, rustproof and acid-proofed steels, high-alloy steel, high-strength sheet metal, cable ducts, supports, sections and panels.

Dimensions:

The extra-thin cutting disc with a disc width of 1.0 mm to 1.9 mm is available in diameters from 115 mm to 230 mm.

Industries:

This makes it the ideal tool for the many applications and challenges in plant and container construction, boiler and tank construction, structural steel engineering, pipeline construction and installation work.

Notice:

The RHODIUS cutting discs for stainless steel are iron- and sulphur-free. To avoid rusting, you should never change from normal steel back to stainless steel with the same disc.

• Little burr formation

• High cutting speed

• Fewer sparks

Machine suitability:

The XTK10 cutting disc is suitable for freehand use on angle grinders.

Material suitability:

The XTK10 has been designed especially for use on stainless steel (SST, Inox), e.g. 1.4031 (X5CrNi18-10 or 304), steel (carbon steel – also termed structural steel, St37, S235JR and 1.0037) and cast steels.

Structure and production:

The cutting disc contains high-quality corundum (aluminium oxide) and 2 full-coverage glass cloth layers. The minimum side load for the cutting disc as defined by EN 12413 and oSa is 40 N (50 N from a diameter of 150 mm). The expiry date (three years) is embossed in the disc hole ring. Consistently high quality is ensured by sophisticated in-process controls applied during manufacturing. To ensure a maximum level of safety, every thousandth disc is tested destructively. This disc features a straight shape (shape 42). The cutting disc is especially stable during cutting.

Quality:

With the XTK10, users get the best RHODIUS tool in its category. RHODIUS TOPline products represent a maximum level of performance and quality.

Applications:

The XTK10 offers an impressively long lifetime (tool life) during use, even in solid material, combined with a very aggressive, light and fast cut. Precise work when processing thin-walled material is also easy to achieve. The disc features minimal sparking, low dust generation and exceptional, vibration-free operation. All of which makes work easier and is especially cost-effective. The disc achieves low angular deviation thanks to its depressed shape. This quality RHODIUS tool is an especially good choice for cutting structural steel, tool steel, spring steels, thin-walled metal sheets, rustproof and acid-proofed steels, high-alloy steel, high-strength sheet metal, cable ducts, supports, sections and panels.

Dimensions:

The extra-thin cutting disc with a disc width of 1.0 mm to 1.9 mm is available in diameters from 115 mm to 230 mm.

Industries:

This makes it the ideal tool for the many applications and challenges in plant and container construction, boiler and tank construction, structural steel engineering, pipeline construction and installation work.

Notice:

The RHODIUS cutting discs for stainless steel are iron- and sulphur-free. To avoid rusting, you should never change from normal steel back to stainless steel with the same disc.

Properties:

Lifetime

Cutting ability for solid material

Cutting ability for thin-walled material

Quality:

Thickness:

Width in mm

Width in mm Material suitability:

Stainless steel

Stainless steel  Steel

Steel Safety instructions:

Iron- and sulphur-free

Iron- and sulphur-free Speed:

m/s

m/s Machine suitability:

Freehand angle grinder

Freehand angle grinder Product variants:

| Product dimensions | Maximum revolutions | Content | Article no. | Product category number | GTIN barcode packing unit |

|---|---|---|---|---|---|

| 115 x 1,0 x 22,23 | 13300 U/min | 50 | 206166 | PK01 | 4011890056653 |

| 115 x 1,5 x 22,23 | 13300 U/min | 50 | 206168 | PK01 | 4011890056646 |

| 125 x 1,0 x 22,23 | 12250 U/min | 50 | 206167 | PK01 | 4011890056622 |

| 125 x 1,5 x 22,23 | 12250 U/min | 50 | 206169 | PK01 | 4011890056608 |

| 180 x 1,5 x 22,23 | 8500 U/min | 25 | 206262 | PK01 | 4011890056691 |

| 230 x 1,9 x 22,23 | 6650 U/min | 25 | 206263 | PK01 | 4011890056783 |

![RHODIUS_sce_Screenshot_XT100EXTENDED_application_2_2020_1280x720px.jpg[28223] RHODIUS_sce_Screenshot_XT100EXTENDED_application_2_2020_1280x720px.jpg[28223]](https://products.rhodius-abrasives.com/media/image/4a/7f/a6/rhodius_sce_screenshot_xt100extended_application_2_2020_1280x720px-jpg_330x330.jpg)

![RHODIUS_ref_LSZF_125_K40_4011890053485_p15.tif[3653] RHODIUS_ref_LSZF_125_K40_4011890053485_p15.tif[3653]](https://products.rhodius-abrasives.com/media/image/55/ea/26/rhodius_ref_lszf_125_k40_4011890053485_p15-jpg_330x330.jpg)