XTK6 EXACT

XTK6 EXACT

Content: 10 Unit

Prices incl. VAT plus shipping costs

- Order number: 210828

- Please select your desired product variant here:

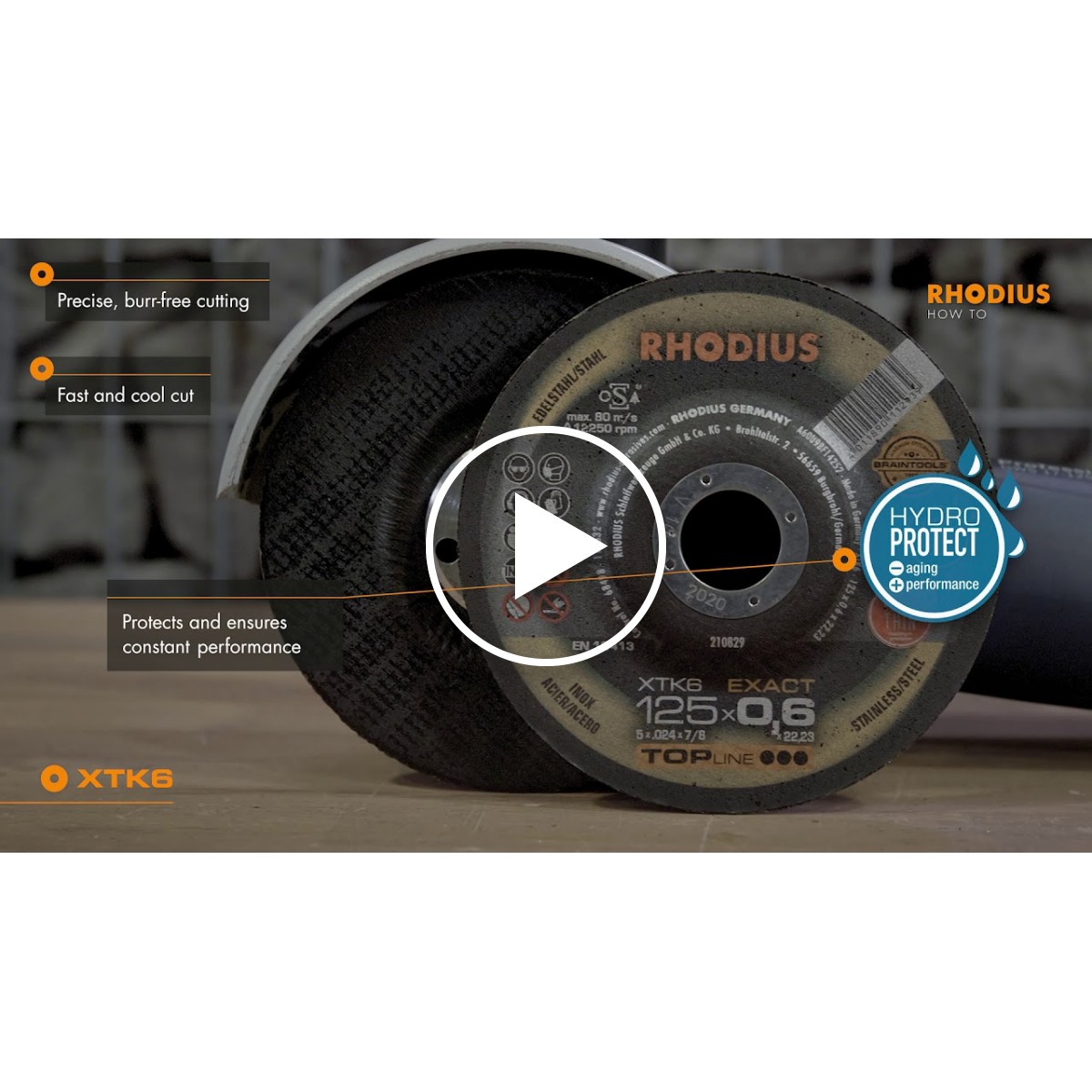

Even less burr formation and even less thermal stress – leading to reduced discoloration. The XTK6 EXACT – the thinnest disc impresses with its ultra-low-noise operation. Thanks to the exceptionally precise, clean and almost burr-free cut, virtually no follow-up work is required. Although just 0.6 mm thick, this slim disc easily cuts very hard materials such as spring steel, stainless steel sheet, etc. Plenty of power in a small form factor: the narrow cut means virtually no contact pressure is required – making work easier and less tiring.

Machine suitability:

The XTK6 EXACT cutting disc is suitable for freehand use with all angle grinders in any performance class (including low-power and battery-powered machines). Battery consumption is very light with this tool. The small contact area keeps energy consumption to a minimum.

Material suitability:

The XTK6 EXACT has been specially designed for use on stainless steel (SST, Inox), e.g. 1.4031 (X5CrNi18-10 or 304), steel (carbon steel – also termed structural steel, St37, S235JR and 1.0037) and cast steels.

Structure and production:

The cutting disc contains high-quality corundum (aluminium oxide) and 2 full-coverage glass cloth layers. The minimum side load for the cutting disc as defined by EN 12413 and oSa is 40 N (50 N from a diameter of 150 mm). The expiry date (three years) is embossed in the disc hole ring. Consistently high quality is ensured by sophisticated in-process controls applied during manufacturing. To ensure a maximum level of safety, every thousandth disc is tested destructively. This disc features a straight shape (shape 42). The cutting disc is especially stable during cutting.

Quality:

With the XTK6 EXACT, users get the best RHODIUS tool in its category. RHODIUS TOPline products represent a maximum level of performance and quality.

Applications:

The XTK6 EXACT offers impressive performance even in solid material, combined with a very aggressive, light and fast cut. The disc stands out with its minimal sparking, low dust generation, smooth, vibration-free operation and very low level of burr formation. This disc also minimises tarnish colouring on the material. All of which makes work easier and is especially cost-effective. High-precision, high-speed processing of thin-walled material is easily achieved. The disc achieves low angular deviation thanks to its depressed shape. The XTK6 EXACT offers users an optimum price/performance ratio. This quality RHODIUS tool is an especially good choice for cutting threaded rods, rustproof and acid-proofed steels, galvanised structural parts and supports. Thanks to its narrow gap widths, this cutting disc is also ideal for MIG welding work and body work processing.

Dimensions:

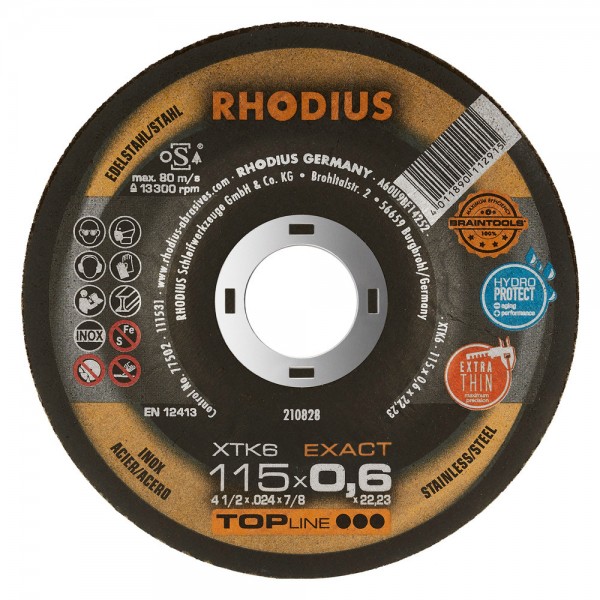

With a disc width of just 0.6 mm, the extra-thin cutting disc is available in the diameters of 115 mm and 125 mm.

Industries:

This is the perfect tool for handling the many applications and challenges facing building fitters, as well as in plant construction, vehicle construction and bodywork, boiler and tank construction, plumbing and installation work.

Notice:

The RHODIUS cutting discs for stainless steel are iron- and sulphur-free. To avoid rusting, you should never change from normal steel back to stainless steel with the same disc.

• The world’s thinnest freehand cutting disc

• Exceptional precision and virtually burr-free

• Minimal thermal stress, resulting in zero blueing

Machine suitability:

The XTK6 EXACT cutting disc is suitable for freehand use with all angle grinders in any performance class (including low-power and battery-powered machines). Battery consumption is very light with this tool. The small contact area keeps energy consumption to a minimum.

Material suitability:

The XTK6 EXACT has been specially designed for use on stainless steel (SST, Inox), e.g. 1.4031 (X5CrNi18-10 or 304), steel (carbon steel – also termed structural steel, St37, S235JR and 1.0037) and cast steels.

Structure and production:

The cutting disc contains high-quality corundum (aluminium oxide) and 2 full-coverage glass cloth layers. The minimum side load for the cutting disc as defined by EN 12413 and oSa is 40 N (50 N from a diameter of 150 mm). The expiry date (three years) is embossed in the disc hole ring. Consistently high quality is ensured by sophisticated in-process controls applied during manufacturing. To ensure a maximum level of safety, every thousandth disc is tested destructively. This disc features a straight shape (shape 42). The cutting disc is especially stable during cutting.

Quality:

With the XTK6 EXACT, users get the best RHODIUS tool in its category. RHODIUS TOPline products represent a maximum level of performance and quality.

Applications:

The XTK6 EXACT offers impressive performance even in solid material, combined with a very aggressive, light and fast cut. The disc stands out with its minimal sparking, low dust generation, smooth, vibration-free operation and very low level of burr formation. This disc also minimises tarnish colouring on the material. All of which makes work easier and is especially cost-effective. High-precision, high-speed processing of thin-walled material is easily achieved. The disc achieves low angular deviation thanks to its depressed shape. The XTK6 EXACT offers users an optimum price/performance ratio. This quality RHODIUS tool is an especially good choice for cutting threaded rods, rustproof and acid-proofed steels, galvanised structural parts and supports. Thanks to its narrow gap widths, this cutting disc is also ideal for MIG welding work and body work processing.

Dimensions:

With a disc width of just 0.6 mm, the extra-thin cutting disc is available in the diameters of 115 mm and 125 mm.

Industries:

This is the perfect tool for handling the many applications and challenges facing building fitters, as well as in plant construction, vehicle construction and bodywork, boiler and tank construction, plumbing and installation work.

Notice:

The RHODIUS cutting discs for stainless steel are iron- and sulphur-free. To avoid rusting, you should never change from normal steel back to stainless steel with the same disc.

Properties:

Lifetime

Cutting ability for solid material

Cutting ability for thin-walled material

Quality:

Thickness:

Width in mm

Width in mm Material suitability:

Stainless steel

Stainless steel  Steel

Steel Safety instructions:

Iron- and sulphur-free

Iron- and sulphur-free Speed:

m/s

m/s Machine suitability:

Freehand angle grinder

Freehand angle grinder Product variants:

| Product dimensions | Maximum revolutions | Content | Article no. | Product category number | GTIN |

|---|---|---|---|---|---|

| 115 × 0.6 × 22.23 | 13300 U/min | 10 | 211301 | PK01 | 4011890124321 |

| 115 × 0.6 × 22.23 | 13300 U/min | 25 | 211300 | PK01 | 4011890124314 |

| 125 × 0.6 × 22.23 | 12250 U/min | 10 | 211302 | PK01 | 4011890124338 |

| 125 × 0.6 × 22.23 | 12250 U/min | 25 | 211295 | PK01 | 4011890124284 |

| 115 × 0.6 × 22.23 | 13300 U/min | 50 | 210828 | PK01 | 4011890112915 |

| 125 × 0.6 × 22.23 | 12250 U/min | 50 | 210829 | PK01 | 4011890112939 |

![Preview: RHODIUS_pic_XTK6_115_4011890112915_10Stk_gestapelt.tif[28720] Preview: RHODIUS_pic_XTK6_115_4011890112915_10Stk_gestapelt.tif[28720]](https://products.rhodius-abrasives.com/media/image/96/ec/8e/rhodius_pic_xtk6_115_4011890112915_10stk_gestapelt-jpg_330x330.jpg)

![Preview: RHODIUS_sce_CUTTING_XTK6_ExtraThinCuttingDiscs_STAINLESSSTEEL (33).tif[11588] Preview: RHODIUS_sce_CUTTING_XTK6_ExtraThinCuttingDiscs_STAINLESSSTEEL (33).tif[11588]](https://products.rhodius-abrasives.com/media/image/a8/8c/f6/rhodius_sce_cutting_xtk6_extrathincuttingdiscs_stainlesssteel-33-jpg_330x330.jpg)

![Preview: RHODIUS_ref_XTK6_125_4011890112939_p01.tif[19996] Preview: RHODIUS_ref_XTK6_125_4011890112939_p01.tif[19996]](https://products.rhodius-abrasives.com/media/image/2a/75/f8/rhodius_ref_xtk6_125_4011890112939_p01-jpg_330x330.jpg)

![RHODIUS_pic_XTK6_115_4011890112915_10Stk_gestapelt.tif[28720]](https://products.rhodius-abrasives.com/media/image/02/15/30/rhodius_pic_xtk6_115_4011890112915_10stk_gestapelt-jpg_600x600.jpg)

![RHODIUS_sce_CUTTING_XTK6_ExtraThinCuttingDiscs_STAINLESSSTEEL (33).tif[11588]](https://products.rhodius-abrasives.com/media/image/e5/4b/0f/rhodius_sce_cutting_xtk6_extrathincuttingdiscs_stainlesssteel-33-jpg_600x600.jpg)

![RHODIUS_ref_XTK6_125_4011890112939_p01.tif[19996]](https://products.rhodius-abrasives.com/media/image/74/g0/f3/rhodius_ref_xtk6_125_4011890112939_p01-jpg_600x600.jpg)

![RHODIUS_sce_Screenshot_XT100EXTENDED_application_2_2020_1280x720px.jpg[28223] RHODIUS_sce_Screenshot_XT100EXTENDED_application_2_2020_1280x720px.jpg[28223]](https://products.rhodius-abrasives.com/media/image/4a/7f/a6/rhodius_sce_screenshot_xt100extended_application_2_2020_1280x720px-jpg_330x330.jpg)

![RHODIUS_ref_LSKFK_125_K40_4011890095652_p15.tif[3649] RHODIUS_ref_LSKFK_125_K40_4011890095652_p15.tif[3649]](https://products.rhodius-abrasives.com/media/image/f5/dc/9f/rhodius_ref_lskfk_125_k40_4011890095652_p15-jpg_330x330.jpg)

![RHODIUS_pic_JUMBOSPEED_115_K40_4011890072097_p15.tif[3503] RHODIUS_pic_JUMBOSPEED_115_K40_4011890072097_p15.tif[3503]](https://products.rhodius-abrasives.com/media/image/19/f3/3b/rhodius_pic_jumbospeed_115_k40_4011890072097_p15-jpg_330x330.jpg)

![RHODIUS_ref_RS580SPEED_125_4011890101414_p01.tif[4117] RHODIUS_ref_RS580SPEED_125_4011890101414_p01.tif[4117]](https://products.rhodius-abrasives.com/media/image/09/5d/d2/rhodius_ref_rs580speed_125_4011890101414_p01-jpg_330x330.jpg)