LGA ALU

LGA ALU

Content: 5 Unit

Prices incl. VAT plus shipping costs

- Order number: 210476

- Please select your desired product variant here:

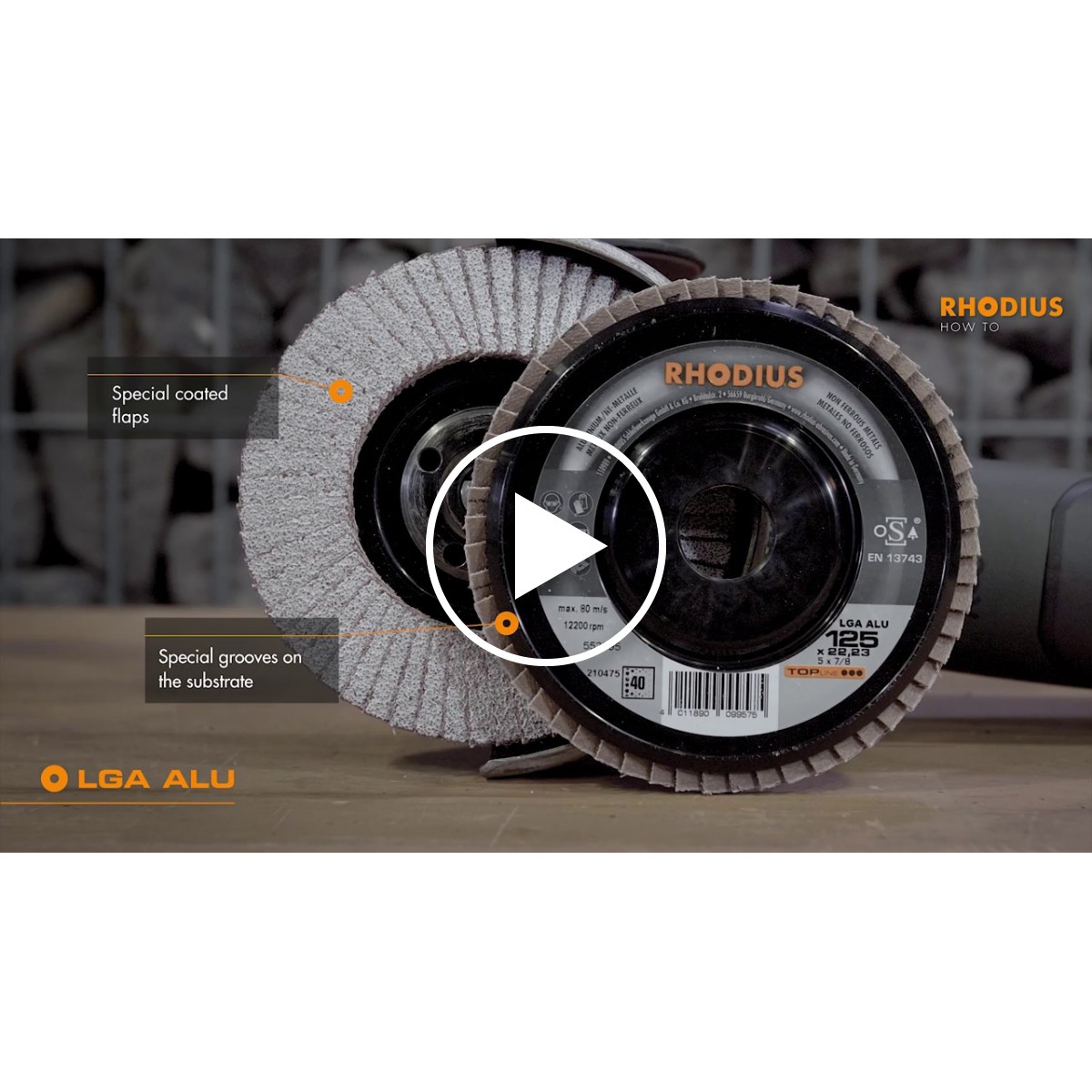

The ideal, long-life flap disc for grinding aluminium and other clog-prone non-ferrous metals.

Machine suitability:

This flap disc is suitable for use on angle grinders from any performance class.

Material suitability:

The RHODIUS LGA ALU flap disc has been developed specially for the processing of non-ferrous metals (aluminium, bronze and brass). The disc offers an impressively long tool life here, coupled with consistently aggressive stock removal.

Structure and production:

The disc is manufactured to EN 13743, safety-tested and certified to oSa standards. The special backing pad is made from ABS. The disc can be trimmed easily. This means that the flap projection can be ground down as it becomes worn out over time, so that the unused grinding surface can then be used to the full. The LGA ALU features a high-quality aluminium oxide (corundum) abrasive grain. This is self-sharpening. All RHODIUS flap discs are also iron- and sulphur-free. With this disc, the flaps lie flat on the disc. This flat arrangement of the flaps makes work considerably easier when an even grinding pattern is required.

Quality:

The LGA ALU provides users with the best RHODIUS tool in its category. RHODIUS TOPline products represent a maximum level of performance and quality.

Applications:

The flaps also feature a special stearate coating that significantly reduces any risk of clogging for this disc. This premium tool is the perfect choice for demanding grinding work and offers an optimum price/performance ratio.

Dimensions:

The flap disc is available in the diameters of 115 mm and 125 mm, and, depending on the variant, in the FEPA grit sizes of 40 and 60.

• Special coating of the flap belt

• Notched carrier for gentle loosening

• Trimmable ABS carrier

Machine suitability:

This flap disc is suitable for use on angle grinders from any performance class.

Material suitability:

The RHODIUS LGA ALU flap disc has been developed specially for the processing of non-ferrous metals (aluminium, bronze and brass). The disc offers an impressively long tool life here, coupled with consistently aggressive stock removal.

Structure and production:

The disc is manufactured to EN 13743, safety-tested and certified to oSa standards. The special backing pad is made from ABS. The disc can be trimmed easily. This means that the flap projection can be ground down as it becomes worn out over time, so that the unused grinding surface can then be used to the full. The LGA ALU features a high-quality aluminium oxide (corundum) abrasive grain. This is self-sharpening. All RHODIUS flap discs are also iron- and sulphur-free. With this disc, the flaps lie flat on the disc. This flat arrangement of the flaps makes work considerably easier when an even grinding pattern is required.

Quality:

The LGA ALU provides users with the best RHODIUS tool in its category. RHODIUS TOPline products represent a maximum level of performance and quality.

Applications:

The flaps also feature a special stearate coating that significantly reduces any risk of clogging for this disc. This premium tool is the perfect choice for demanding grinding work and offers an optimum price/performance ratio.

Dimensions:

The flap disc is available in the diameters of 115 mm and 125 mm, and, depending on the variant, in the FEPA grit sizes of 40 and 60.

Properties:

Lifetime

Stock removal

Quality:

Thickness:

Grain

Grain Material suitability:

Wood

Wood  Non-ferrous metals

Non-ferrous metals Speed:

m/s

m/s Machine suitability:

Freehand angle grinder

Freehand angle grinder Product variants:

| Product dimensions | Grain SU | Maximum revolutions | Content | Article no. | Product category number | GTIN barcode packing unit |

|---|---|---|---|---|---|---|

| 125 x 22,23 | 40 | 12250 U/min | 5 | 211314 | PK05 | 4011890124451 |

| 115 x 22,23 | 40 | 13300 U/min | 10 | 210473 | PK05 | 4011890099674 |

| 125 x 22,23 | 60 | 12250 U/min | 5 | 211315 | PK05 | 4011890124468 |

| 115 x 22,23 | 60 | 13300 U/min | 10 | 210474 | PK05 | 4011890099698 |

| 125 x 22,23 | 40 | 12250 U/min | 10 | 210475 | PK05 | 4011890099582 |

| 125 x 22,23 | 60 | 12250 U/min | 10 | 210476 | PK05 | 4011890099711 |

![Preview: RHODIUS_sce_Screenshot_LGAALU_application_1_2020_1280x720px.jpg[28232] Preview: RHODIUS_sce_Screenshot_LGAALU_application_1_2020_1280x720px.jpg[28232]](https://products.rhodius-abrasives.com/media/image/14/a9/9b/rhodius_sce_screenshot_lgaalu_application_1_2020_1280x720px-jpg_330x330.jpg)

![RHODIUS_sce_Screenshot_LGAALU_application_1_2020_1280x720px.jpg[28232]](https://products.rhodius-abrasives.com/media/image/f7/b5/e7/rhodius_sce_screenshot_lgaalu_application_1_2020_1280x720px-jpg_600x600.jpg)

![RHODIUS_pic_JUMBOSPEED_115_K40_4011890072097_p15.tif[3503] RHODIUS_pic_JUMBOSPEED_115_K40_4011890072097_p15.tif[3503]](https://products.rhodius-abrasives.com/media/image/19/f3/3b/rhodius_pic_jumbospeed_115_k40_4011890072097_p15-jpg_330x330.jpg)

![RHODIUS_ref_XT24_125_4011890098820_p01.tif[3075] RHODIUS_ref_XT24_125_4011890098820_p01.tif[3075]](https://products.rhodius-abrasives.com/media/image/a0/5c/10/rhodius_ref_xt24_125_4011890098820_p01-jpg_330x330.jpg)