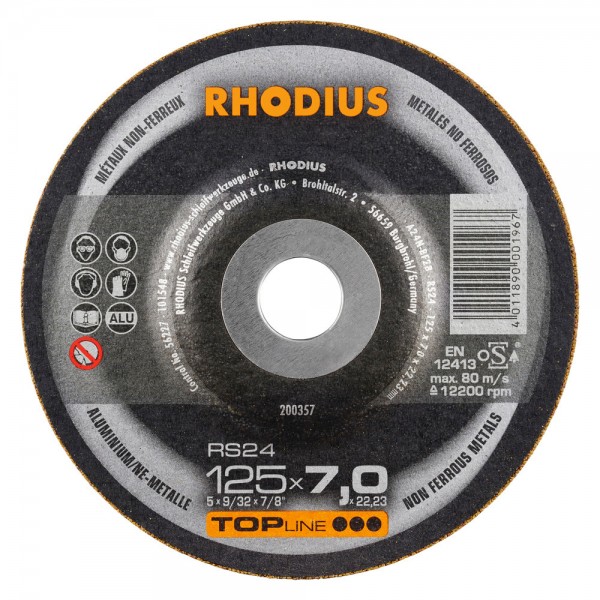

RS24

RS24

Content: 10 Unit

Prices incl. VAT plus shipping costs

- Order number: 200349

- Please select your desired product variant here:

Grinding disc with special filler materials prevents clogging while ensuring efficient and continuous grinding.

Machine suitability:

The RHODIUS RS24 FUSION is a grinding disc (shape 27) for angle grinders in any performance class.

Material suitability:

The RHODIUS RS24 has been developed specially for the processing of non-ferrous metals (such as aluminium, bronze and brass). The RS24 grinding disc is an excellent choice for chamfering, welding seam preparation, for finishing work on welding seams, as well as for deburring work and rounding off edges. This tool is also suitable for surface grinding work.

Structure and production:

The disc is manufactured to EN 12413, safety-tested and certified to oSa standards. Every thousandth disc undergoes safety testing at almost double the normal working speed. The product features a high-quality abrasive grain mix of silicon carbide (SiC) and aluminium oxide (corundum) plus a matching phenol resin formulation, and is reinforced by three full-coverage glass cloth layers. This grinding disc therefore comfortably exceeds the side load criterion of 290 N required by safety regulations.

Quality:

With the RS24, users get the best RHODIUS tool in its category. RHODIUS TOPline products represent a maximum level of performance and quality.

Applications:

The RS24 offers an impressive and aggressive level of stock removal performance.

Dimensions:

The RS24 grinding disc has a disc width of 7.0 mm, and is available in diameters from 115 mm to 230 mm.

Industries:

This grinding disc is the preferred choice for tasks in metalwork shops and in shipyards.

• High stock removal performance

• No clogging of the disc

• Minimum material heating

Machine suitability:

The RHODIUS RS24 FUSION is a grinding disc (shape 27) for angle grinders in any performance class.

Material suitability:

The RHODIUS RS24 has been developed specially for the processing of non-ferrous metals (such as aluminium, bronze and brass). The RS24 grinding disc is an excellent choice for chamfering, welding seam preparation, for finishing work on welding seams, as well as for deburring work and rounding off edges. This tool is also suitable for surface grinding work.

Structure and production:

The disc is manufactured to EN 12413, safety-tested and certified to oSa standards. Every thousandth disc undergoes safety testing at almost double the normal working speed. The product features a high-quality abrasive grain mix of silicon carbide (SiC) and aluminium oxide (corundum) plus a matching phenol resin formulation, and is reinforced by three full-coverage glass cloth layers. This grinding disc therefore comfortably exceeds the side load criterion of 290 N required by safety regulations.

Quality:

With the RS24, users get the best RHODIUS tool in its category. RHODIUS TOPline products represent a maximum level of performance and quality.

Applications:

The RS24 offers an impressive and aggressive level of stock removal performance.

Dimensions:

The RS24 grinding disc has a disc width of 7.0 mm, and is available in diameters from 115 mm to 230 mm.

Industries:

This grinding disc is the preferred choice for tasks in metalwork shops and in shipyards.

Properties:

Lifetime

Stock removal

Quality:

Thickness:

Width in mm

Width in mm Material suitability:

Non-ferrous metals

Non-ferrous metals Speed:

m/s

m/s Machine suitability:

Freehand angle grinder

Freehand angle grinder Product variants:

| Product dimensions | Maximum revolutions | Content | Article no. | Product category number | GTIN barcode packing unit |

|---|---|---|---|---|---|

| 115 x 7,0 x 22,23 | 13300 U/min | 25 | 200349 | PK04 | 4011890044414 |

| 125 x 7,0 x 22,23 | 12250 U/min | 25 | 200357 | PK04 | 4011890044421 |

| 180 x 7,0 x 22,23 | 8500 U/min | 10 | 200364 | PK04 | 4011890044438 |

| 230 x 7,0 x 22,23 | 6650 U/min | 10 | 200377 | PK04 | 4011890044452 |

![RHODIUS_ref_RS580SPEED_125_4011890101414_p01.tif[4117] RHODIUS_ref_RS580SPEED_125_4011890101414_p01.tif[4117]](https://products.rhodius-abrasives.com/media/image/09/5d/d2/rhodius_ref_rs580speed_125_4011890101414_p01-jpg_330x330.jpg)

![RHODIUS_ref_XT24_125_4011890098820_p01.tif[3075] RHODIUS_ref_XT24_125_4011890098820_p01.tif[3075]](https://products.rhodius-abrasives.com/media/image/a0/5c/10/rhodius_ref_xt24_125_4011890098820_p01-jpg_330x330.jpg)

![RHODIUS_sce_Screenshot_LGAALU_application_1_2020_1280x720px.jpg[28232] RHODIUS_sce_Screenshot_LGAALU_application_1_2020_1280x720px.jpg[28232]](https://products.rhodius-abrasives.com/media/image/14/a9/9b/rhodius_sce_screenshot_lgaalu_application_1_2020_1280x720px-jpg_330x330.jpg)