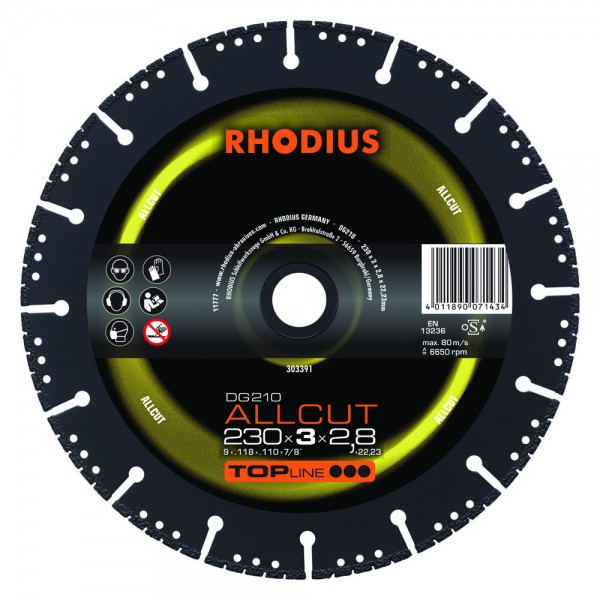

DG210 ALLCUT

DG210 ALLCUT

Content: 1 Unit

Prices incl. VAT plus shipping costs

- Order number: 303387

- Please select your desired product variant here:

With the DG210 ALLCUT, the user gets a real universal disc. It offers an impressively constant cutting performance in a variety of materials. The cooling holes below the segments prevent the steel core from overheating. Vacuum-brazed. Suitable for wet and dry cutting.

Machine suitability:

The DG210 ALLCUT diamond cutting disc is designed both for freehand use and for use on a stationary machine: for angle grinders, petrol cut-off saws and table saws (depending on diameter). This product shows its strengths on machines in any performance class but especially when used on high-performance machines.

Material suitability:

The DG210 ALLCUT was specifically developed for processing reinforcing steel and light structural steel. This RHODIUS quality tool is also an excellent choice when working with granite, hard concrete with aggregates, marble, paving stones, clay roofing tiles, hard masonry bricks, reinforced concrete and ferroconcrete, concrete and paving bricks, hard stone and flagstones, concrete tubes or kerbstones, medium-hard masonry bricks, slate, hard sand-lime bricks, hard precast concrete blocks, stone blocks, concrete roofing tiles, sandstone, hollow stone blocks and soft concrete blocks.

Structure and production:

The DG210 ALLCUT features a segmented rim. This enables very high cutting speeds to be achieved while also maximising tool life. The tool has been tested to EN 13236 and oSa, and can be used both in wet cutting and dry cutting applications. Use of high-quality industrial diamonds makes the DG210 ALLCUT a particularly powerful tool. The disc is vacuum brazed.

Quality:

With the DG210 ALLCUT, users get the best RHODIUS tool in its category. RHODIUS TOPline products represent a maximum level of performance and quality.

Dimensions:

This diamond cutting disc is available in diameters from 115 mm to 500 mm.

• Versatile disc for use in a variety of materials

• Constant cutting performance

• Cooling holes below the segments prevent overheating

• Wet and dry cutting

• Vacuum-brazed

Machine suitability:

The DG210 ALLCUT diamond cutting disc is designed both for freehand use and for use on a stationary machine: for angle grinders, petrol cut-off saws and table saws (depending on diameter). This product shows its strengths on machines in any performance class but especially when used on high-performance machines.

Material suitability:

The DG210 ALLCUT was specifically developed for processing reinforcing steel and light structural steel. This RHODIUS quality tool is also an excellent choice when working with granite, hard concrete with aggregates, marble, paving stones, clay roofing tiles, hard masonry bricks, reinforced concrete and ferroconcrete, concrete and paving bricks, hard stone and flagstones, concrete tubes or kerbstones, medium-hard masonry bricks, slate, hard sand-lime bricks, hard precast concrete blocks, stone blocks, concrete roofing tiles, sandstone, hollow stone blocks and soft concrete blocks.

Structure and production:

The DG210 ALLCUT features a segmented rim. This enables very high cutting speeds to be achieved while also maximising tool life. The tool has been tested to EN 13236 and oSa, and can be used both in wet cutting and dry cutting applications. Use of high-quality industrial diamonds makes the DG210 ALLCUT a particularly powerful tool. The disc is vacuum brazed.

Quality:

With the DG210 ALLCUT, users get the best RHODIUS tool in its category. RHODIUS TOPline products represent a maximum level of performance and quality.

Dimensions:

This diamond cutting disc is available in diameters from 115 mm to 500 mm.

Properties:

Lifetime

Cutting ability

Quality:

Thickness:

Segment height for segmented diamond cutting discs

Segment height for segmented diamond cutting discs Material suitability:

All-round

All-round Safety instructions:

Nasschnitt

Nasschnitt  Trockenschnitt

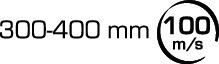

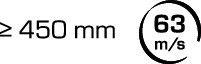

Trockenschnitt Speed:

m/s

m/s  m/s

m/s  m/s

m/s Machine suitability:

Freehand angle grinder

Freehand angle grinder *Reducer ring to hole diameter of 20.00 mm included in each packing unit.

Product variants:

| Product dimensions | Maximum revolutions | Content | Article no. | Product category number | GTIN barcode packing unit | Machine suitability |

|---|---|---|---|---|---|---|

| 115 x 3,0 x 2,5 x 22,23 | 13300 U/min | 1 | 303387 | PK10 | 4011890071397 | Freehand angle grinder |

| 125 x 3,0 x 2,5 x 22,23 | 12250 U/min | 1 | 303388 | PK10 | 4011890071403 | Freehand angle grinder |

| 150 x 3,0 x 2,5 x 22,23 | 10200 U/min | 1 | 303389 | PK10 | 4011890071410 | Freehand angle grinder |

| 180 x 3,0 x 2,8 x 22,23 | 8500 U/min | 1 | 303390 | PK10 | 4011890071427 | Freehand angle grinder |

| 230 x 3,0 x 2,8 x 22,23 | 6650 U/min | 1 | 303391 | PK10 | 4011890071434 | Freehand angle grinder |

| 300 x 3,0 x 3,1 x 25,40* | 6400 U/min | 1 | 303366 | PK10 | 4011890071441 | Table saw Petrol-driven cutting machine |

| 350 x 3,0 x 3,1 x 25,40* | 5500 U/min | 1 | 303368 | PK10 | 4011890071465 | Table saw Petrol-driven cutting machine |

| 400 x 3,0 x 3,3 x 25,40* | 4800 U/min | 1 | 303369 | PK10 | 4011890071472 | Table saw Petrol-driven cutting machine |

| 500 x 3,0 x 3,9 x 25,40* | 2450 U/min | 1 | 303370 | PK10 | 4011890071489 | Freehand angle grinder Petrol-driven cutting machine Mobile cutting/grinding machine Table saw |