KFS

KFS

Content: 25 Unit

Prices incl. VAT plus shipping costs

- Order number: 304284

- Please select your desired product variant here:

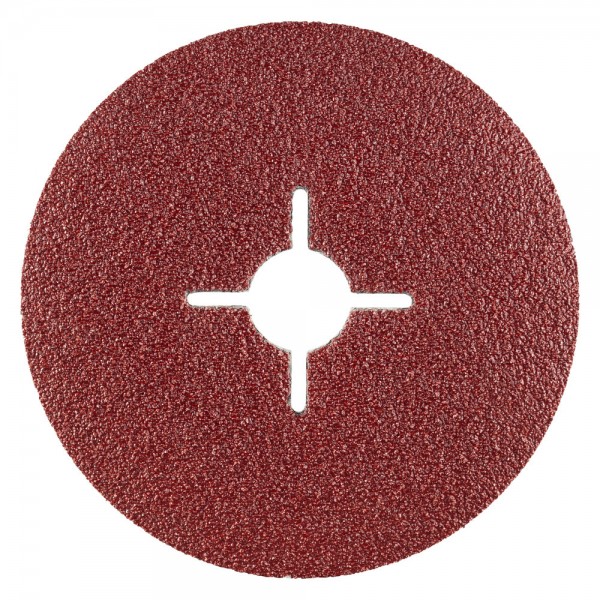

Aluminium oxide fibre disc – the grain enables superior stock removal performance on steel.

Machine suitability:

This fibre disc must be used together with a matching backing pad, such as the RHODIUS RH ST. Also ensure that the backing pad used has the right diameter.

Material suitability:

Featuring high-quality aluminium oxide (corundum), the RHODIUS KFS fibre disc has been specifically developed for processing steel (carbon steel – also termed structural steel, St37, S235JR and 1.0037).

Quality:

The KFS gives users a tool that easily meets the demanding requirements for quality in manufacturing and the skilled trades. To help make work even more cost-effective, RHODIUS fibre discs from the premium TOP line are recommended.

Applications:

The disc contains no iron or sulphur.

Dimensions:

This fibre disc is available in the diameters of 100 mm to 180 mm and, depending on the individual variant, grits in the FEPA grit sizes of 16, 24, 36, 40, 60, 80, 100 and 120.

• Good stock removal performance

• Long lifetime

• Few sparks

Machine suitability:

This fibre disc must be used together with a matching backing pad, such as the RHODIUS RH ST. Also ensure that the backing pad used has the right diameter.

Material suitability:

Featuring high-quality aluminium oxide (corundum), the RHODIUS KFS fibre disc has been specifically developed for processing steel (carbon steel – also termed structural steel, St37, S235JR and 1.0037).

Quality:

The KFS gives users a tool that easily meets the demanding requirements for quality in manufacturing and the skilled trades. To help make work even more cost-effective, RHODIUS fibre discs from the premium TOP line are recommended.

Applications:

The disc contains no iron or sulphur.

Dimensions:

This fibre disc is available in the diameters of 100 mm to 180 mm and, depending on the individual variant, grits in the FEPA grit sizes of 16, 24, 36, 40, 60, 80, 100 and 120.

Properties:

Quality:

Thickness:

Grain

Grain Material suitability:

Steel

Steel Speed:

m/s

m/s Machine suitability:

Freehand angle grinder

Freehand angle grinder Product variants:

| Product dimensions | Grain SU | Maximum revolutions | Content | Article no. | Product category number | GTIN barcode packing unit |

|---|---|---|---|---|---|---|

| 100 x 16,00 | 16 | 15300 U/min | 25 | 304284 | PK06 | 4011890115565 |

| 100 x 16,00 | 24 | 15300 U/min | 25 | 304285 | PK06 | 4011890115572 |

| 100 x 16,00 | 36 | 15300 U/min | 25 | 304286 | PK06 | 4011890115589 |

| 100 x 16,00 | 40 | 15300 U/min | 25 | 304287 | PK06 | 4011890115596 |

| 100 x 16,00 | 60 | 15300 U/min | 25 | 304288 | PK06 | 4011890115619 |

| 100 x 16,00 | 80 | 15300 U/min | 25 | 304289 | PK06 | 4011890115626 |

| 100 x 16,00 | 100 | 15300 U/min | 25 | 304283 | PK06 | 4011890115633 |

| 100 x 16,00 | 120 | 15300 U/min | 25 | 304290 | PK06 | 4011890115640 |

| 115 x 22,23 | 16 | 13300 U/min | 25 | 300001 | PK06 | 4011890082812 |

| 115 x 22,23 | 24 | 13300 U/min | 25 | 300002 | PK06 | 4011890043684 |

| 115 x 22,23 | 36 | 13300 U/min | 25 | 300003 | PK06 | 4011890082829 |

| 115 x 22,23 | 40 | 13300 U/min | 25 | 300004 | PK06 | 4011890043691 |

| 115 x 22,23 | 50 | 13300 U/min | 25 | 300005 | PK06 | 4011890082836 |

| 115 x 22,23 | 60 | 13300 U/min | 25 | 300006 | PK06 | 4011890082843 |

| 115 x 22,23 | 80 | 13300 U/min | 25 | 300007 | PK06 | 4011890082850 |

| 115 x 22,23 | 100 | 13300 U/min | 25 | 300008 | PK06 | 4011890082867 |

| 115 x 22,23 | 120 | 13300 U/min | 25 | 300009 | PK06 | 4011890082874 |

| 125 x 22,23 | 16 | 12250 U/min | 25 | 300057 | PK06 | 4011890082881 |

| 125 x 22,23 | 24 | 12250 U/min | 25 | 300058 | PK06 | 4011890082898 |

| 125 x 22,23 | 36 | 12250 U/min | 25 | 300059 | PK06 | 4011890082904 |

| 125 x 22,23 | 40 | 12250 U/min | 25 | 300060 | PK06 | 4011890082911 |

| 125 x 22,23 | 50 | 12250 U/min | 25 | 300061 | PK06 | 4011890082928 |

| 125 x 22,23 | 60 | 12250 U/min | 25 | 300062 | PK06 | 4011890082935 |

| 125 x 22,23 | 80 | 12250 U/min | 25 | 300063 | PK06 | 4011890082942 |

| 125 x 22,23 | 100 | 12250 U/min | 25 | 300064 | PK06 | 4011890082959 |

| 125 x 22,23 | 120 | 12250 U/min | 25 | 300065 | PK06 | 4011890082966 |

| 150 x 22,23 | 24 | 10200 U/min | 25 | 305539 | PK06 | 4011890115664 |

| 150 x 22,23 | 36 | 10200 U/min | 25 | 305540 | PK06 | 4011890115671 |

| 150 x 22,23 | 40 | 10200 U/min | 25 | 305541 | PK06 | 4011890091814 |

| 150 x 22,23 | 60 | 10200 U/min | 25 | 305542 | PK06 | 4011890115688 |

| 150 x 22,23 | 80 | 10200 U/min | 25 | 305543 | PK06 | 4011890115695 |

| 150 x 22,23 | 120 | 10200 U/min | 25 | 305544 | PK06 | 4011890115701 |

| 180 x 22,23 | 16 | 8500 U/min | 25 | 300127 | PK06 | 4011890082973 |

| 180 x 22,23 | 24 | 8500 U/min | 25 | 300128 | PK06 | 4011890082980 |

| 180 x 22,23 | 36 | 8500 U/min | 25 | 300129 | PK06 | 4011890082997 |

| 180 x 22,23 | 40 | 8500 U/min | 25 | 300130 | PK06 | 4011890083000 |

| 180 x 22,23 | 60 | 8500 U/min | 25 | 300132 | PK06 | 4011890083017 |

| 180 x 22,23 | 80 | 8500 U/min | 25 | 300133 | PK06 | 4011890083024 |

| 180 x 22,23 | 120 | 8500 U/min | 25 | 300135 | PK06 | 4011890083031 |